Founded in 1952

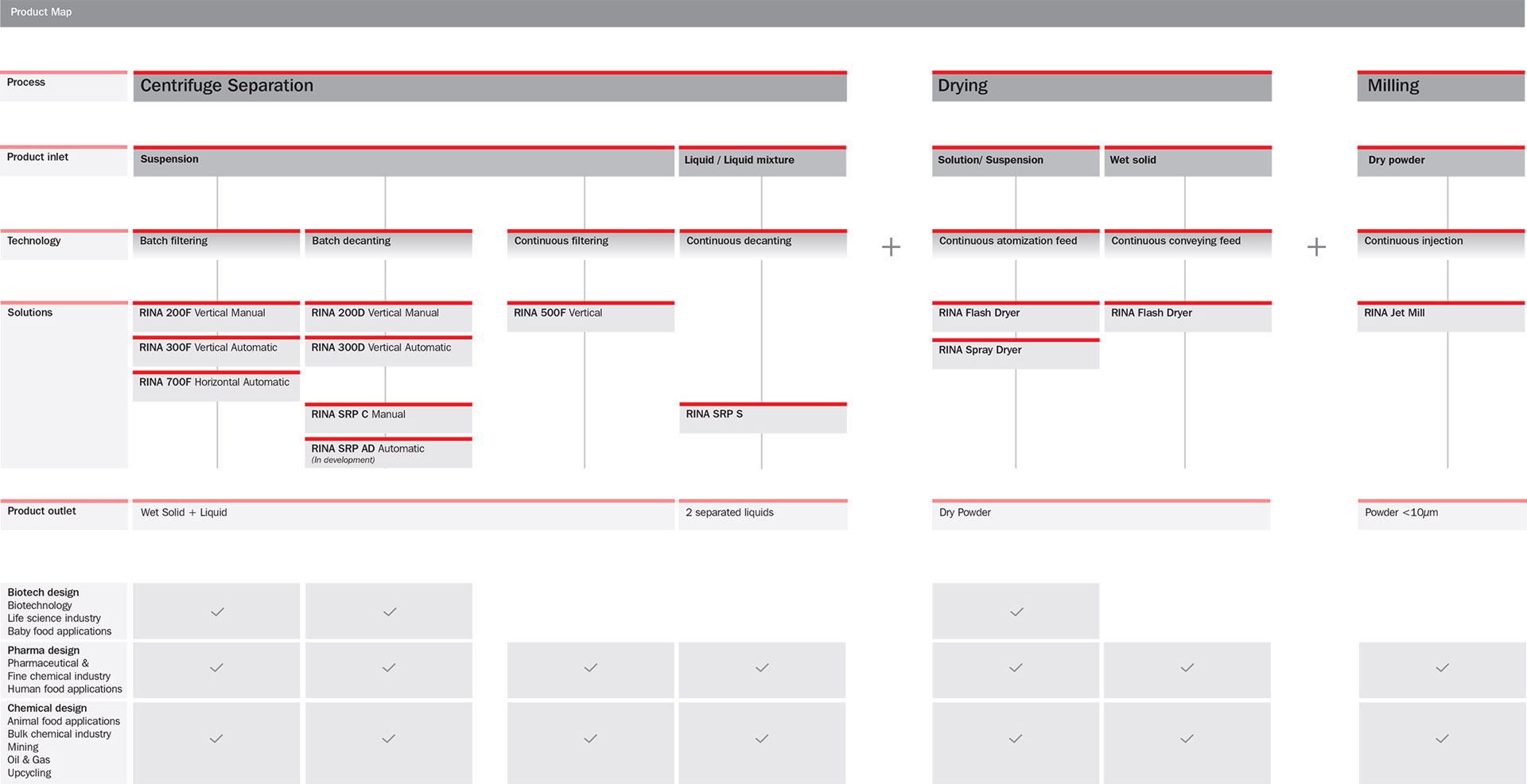

Riera Nadeu, S.A. is a leader in the manufacturing of industrial equipment for centrifuge separation, pneumatic drying system and powder milling.

Our company was founded with the objective of offering the accurate technical solutions to the growing chemical activity in the region of Barcelona. We became rapidly an important supplier for the local industry. Following the trend of markets globalization, our projection became more and more wide.

Our policy of excellence in all the manufacturing procedures, detailed finishing and commercialization, have led us to be a reference on national and international markets.

We are now counting with more than 2000 references working for the most demanding applications such as Biotechnology, Pharma, Food, Chemicals, Energy and Upcycling.

72 Years of Experience

Our Story

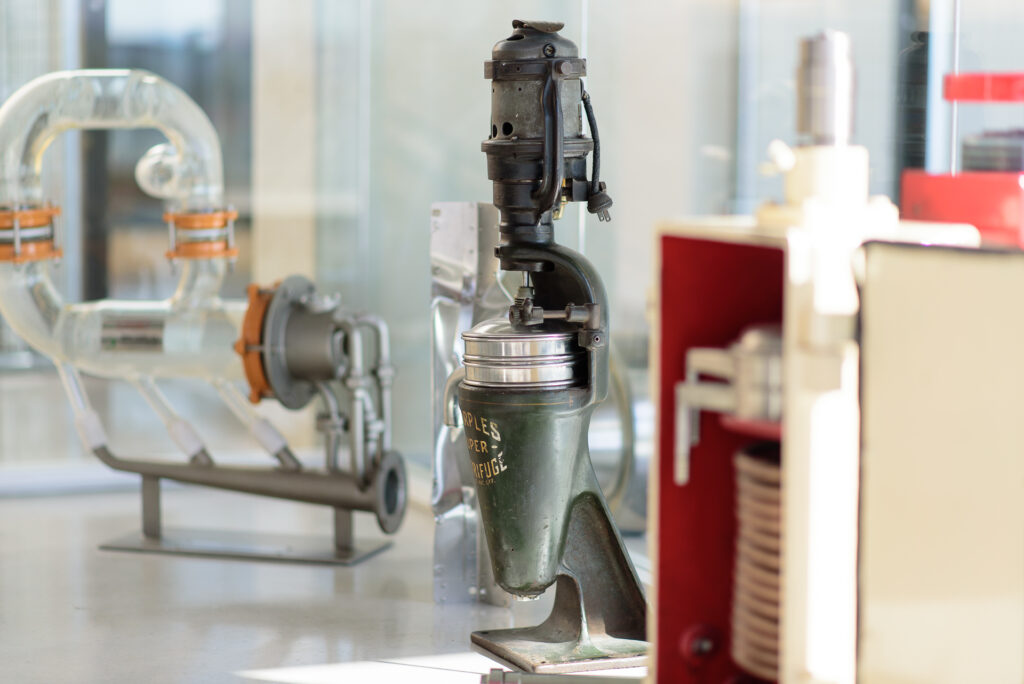

1952

Creation of Riera Nadeu as a manufacturer of Batch centrifuges and Supercentrifuges.

1971

First automatic batch centrifuges bottom discharge RINA 300F.

1982

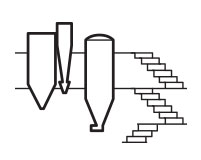

Equipment for continuous processes with filtering centrifuges RINA 500F, RINA Flash Dryers and Micronizers RINA Jet Mills.

1988

Biotech and Pharma versions of horizontal batch centrifuges RINA 700F for the highest quality requirements.

2010

Extended range of dryers with the RINA Spray Dryer solutions.

Coming next

First Supercentrifuge with Automatic Discharge RINA SRP-AD.

Family identity, vision of the future.

Directed by Riera family, our company is an engineering competence center equipped with an ultra-modern workshop.

The RINA brand name of our products and services is a synonym of commitment, empathy and quality.

Our essence is to generate reliable and stable cooperation for the wellbeing business of our clients and the strategic development of their production plant.

Our philosophy: RN_ 360

We are supporting your projects with all our resources and experience to guarantee the supply of the best equipment and best service.

The relationship with our clients is defined as a collaborative 360º cycle covering all the stages of a project lifetime from design definition until process adjustments and optimization.

We warrant the good adequacy between your requirements and the delivered value. The satisfaction of our partners is the leitmotif of our daily work.

The chain of values from Riera Nadeu.

Riera Nadeu strictly does not accept any kind of material or service arising from countries whose governments and policies are not guaranteeing completion with the protection of human rights and environment.

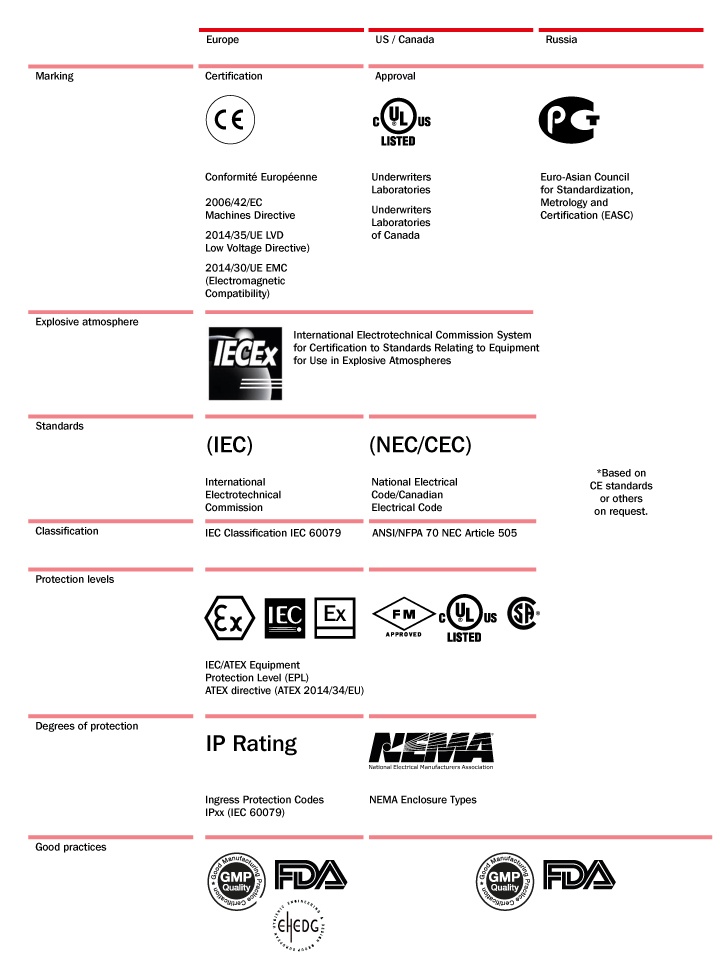

All raw material and incorporated components are purchased to selected and well-known qualified suppliers providing CE mark and/or US safety conformity. From the very beginning of the manufacture until the delivery, we guarantee 100% traceability of all the parts.

Our facilities are open at any time to receive our customers. All the equipments and installations are supplied with the corresponding manual of instructions, technical documentation of the components, material certificates and the mandatory acceptance tests protocol (FAT).

Design & Manufacturing Philosophy

Each project is a challenge

Innovation and global quality from Barcelona

Our facilities are located in Granollers, a city near Barcelona. Our modern plant is equipped with cutting-edge machine tools, test-center, laboratory, engineering and after-sales services.

All our equipments are manufactured in our workshop located in Granollers, Barcelona.

Riera Nadeu has been awarded the ISO 9001 quality certification.

Our ethic commitment is total within the industrial ecosystem, driven by innovation, sustainable development and an active policy towards social considerations.

Quality in Electrical Design

The RINA machines are designed to work automatically adapting their functional modes to the process requirements of the Clients.

We are proposing a total flexibility when integrating the equipment in the Client’s environment and providing the most reliable solution for the process.

We collaborate with the most important and internationally recognized suppliers ensuring the maximum quality of service. Our designs are constantly moving towards the specifications of the industry 4.0.

Mechanical Quality

Our mechanical design prioritizes robustness and reliability, considering ergonomics for the user and for maintenance operations.

We guarantee the highest quality level in the procurement of raw materials, the choice of sub-vendors, the manufacturing of parts and their assembly.

Our workforce is counting with very high skilled homologated welders and welding procedures. We are working with all main type of steels: Stainless Steel, Duplex and SuperDuplex, Hastelloy, etc. …, in compliance with the most demanding requirements.

Global Service

We guarantee the success of the project by accompanying our Clients from the early phase of the engineering study to the implementation and commissioning of the equipment at site.

Our designing team customizes each machine to your needs and specifications completing the service with technical consultancy and risk analysis support.

During the delivery phase, the Riera Nadeu’s team supervises the assembly and carries out the pre-commissioning, commissioning, start-up and training assistance.

If the customer requires it, we are providing support to the IQ and OQ implementation.

Our designs comply with the regulations in force in the country where the equipment is being installed and operated.

The safety functions are studied and calculated to achieve a Performance Level equivalent to SIL2.