Compacity, productivity and modularity.

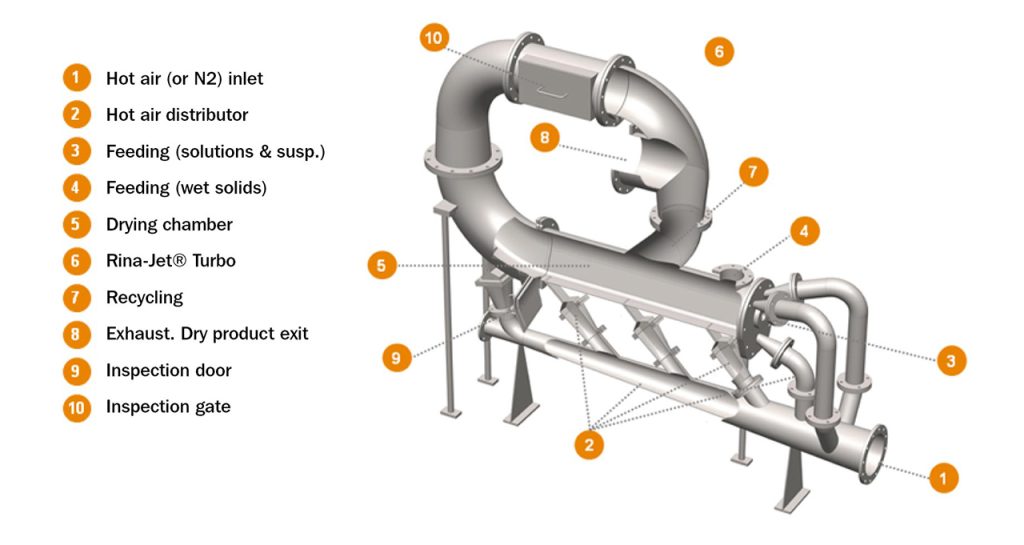

Continuous pneumatic dryer

The RINA Flash Dryer models are working in a continuous way by atomizing slurries or dosing wet solid in a toroidal or straight drying chamber.

This technological solution is particularly recommended for products that can be dried with high temperature for the instantaneous evaporation of the liquid.

Riera Nadeu accumulates experience with product from the Mining, Chemical, Pharmaceutical and many other industries.

When a suspension needs to be dried by atomization, the chamber is equipped with a bi-fluid nozzle and works with an elevated temperature to evaporate the liquid in the shortest time. When the product is a disaggregated wet solid, it is fed with dosing screw conveyor and/or a rotary valve.

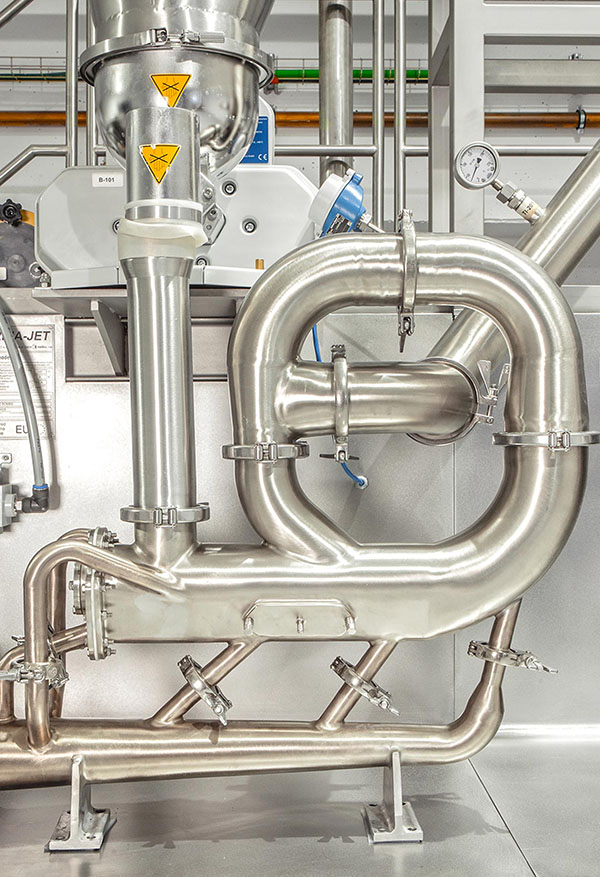

The toroidal design of the chamber generates a turbulent regime in the drying section. The combination of turbulences of hot fluid with the vacuum created by the high speed of the particles is eliminating the liquid surrounding them. Moreover, the turbulences are disaggregating the product in order to recover a dry powder with fine granulometry. The toroidal design is working as a centrifugal classifier forcing the heavy particles to re-circulate (due to aggregates or high residual moisture).

The straight design generates a laminar regime without any impact on the final particle size.

The mixed fluid made of vapor and dry particles is pneumatically conveyed to some powder separation system. Several configurations can be proposed: cyclone, bag filter, scrubber to reduce the loss of fine particles at its minimum to comply with local requirements in terms of emission.

The installations RINA Flash Dryer are modular, compact, with only few parts in movement and low maintenance cost. They can be adapted to the general arrangement of the production plant.

The treatment of abrasive products can require a lining of the equipment with some special material.

From the safety point of view, they can be adapted to work in explosive hazardous area with the relevant certification or approval for the operating location. The drying line can be working in closed loop circuit with Nitrogen if needed.

| Models | Evaporation water Kg/h | Up to | Throughput (Wet product) Kg/h | Up to | Dry product Kg/h | Up to |

| S-Lab | 1 | 4 | 2 | 10 | 0,5 | 6 |

| S-605 | 15 | 75 | 25 | 125 | 10 | 100 |

| S-806 | 50 | 105 | 100 | 200 | 75 | 225 |

| S-1008 | 125 | 250 | 200 | 400 | 175 | 225 |

| S-1210 | 200 | 350 | 350 | 600 | 300 | 500 |

| S-1412 | 300 | 500 | 500 | 1000 | 450 | 900 |

| S-1816 | 400 | 1000 | 750 | 1500 | 600 | 1250 |

| S-2018 | 750 | 1750 | 1200 | 3000 | 1000 | 2750 |

| S-2220 | 1000 | 2200 | 2500 | 5000 | 1500 | 3250 |

| S-2422 | 1250 | 2500 | 2500 | 6500 | 1750 | 5000 |

| S-2824 | 1500 | 3000 | 2500 | 8000 | 2500 | 6000 |

| S-3632 | 1500 | 3500 | 5000 | 12500 | 2750 | 10000 |